Flexible Gas Hose

UNCOATED TYPE

Use in clean rooms of semiconductor factories such as PDP, TFT, LCD that is available with a regular sprinklers

- Stainless Steel 304

- Zinc-plated Steel (Nut & Nipple)

- EPDM Sealing Gasket

- Nylon Isolating Ring

- KFI Approved

DOUBLE COATED TYPE

Use in clean rooms of semiconductor factories such as PDP, TFT, LCD that is available with a regular sprinklers

- Stainless Steel 304

- Zinc-plated Steel (Nut & Nipple)

- EPDM Sealing Gasket

- Nylon Isolating Ring

- KFI Approved

- Passed strict standards and inspection by KS standard (KSD 3625) and Korea Gas Safety Corporation (KGS)

- Insulation ring is inserted to prevent gas explosion accident due to micro current, so it is safe from the danger of gas leakage

- Excellent gas proof and no permeability, It is possible even after abolition of a long time cock.

| ominal diameter | Inner diameter | Outer diameter | Screw Nominal | Minimum radius of curvature | Standard length (mm) | Tube thickness |

|---|---|---|---|---|---|---|

| 15A | 13.7 | 19.2 | PT 1/2" | 30 Below | 500mm~3000mm | 0.25mm over |

| 20A | 19.7 | 25.2 | PT 1/2" | 40 Below | 500mm~3000mm | |

| 25A | 25.7 | 31.2 | PT 1" | 50 Below | 500mm~3000mm |

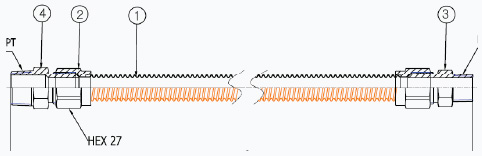

Stainless Steel (Uncoated)

Stainless Steel (Uncoated)

Stainless Steel (Uncoated)

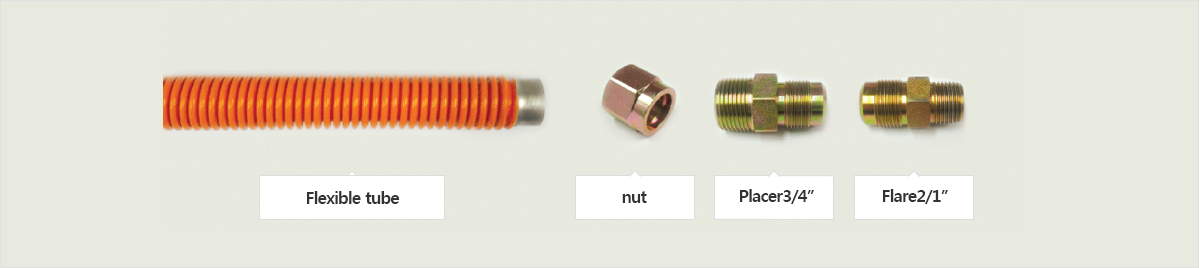

| NO | Part Name | material | Remarks |

|---|---|---|---|

| 1 | Flexible cube | STS304 | PT 0.25mm over/2" |

| 2 | Nuts | SS400 | Zinc plating" |

| 3 | Flare Nipple 1/2 | SS400 | |

| 4 | Flare Nipple 3/4 | SS400 |

| Performance test items | test conditions | Performance | |

|---|---|---|---|

| Confidential Performance | 0.02 Mpa, 1 minute, air pressure | No leakage. | |

| Withstand pressure performance | 610mm hose, 1.8Mpa, water pressure for 1 minute | No leakage, no other abnormality | |

| Lelease performance | 305mm Hose airtight test after 5 minutes of load release test | no abnormalities such as separation of fittings, breakage and leakage of hoses. | |

| Torsional Performance | 610mm Hose Torsional 90 degree torsion at uniform speed of 10-12 sec. | no damage, cracks, exposure, etc. | |

| Bending performance | 610mm hose, U-shaped bending at a uniform speed of 10-12 seconds per time 30 times each left and right | No leakage, breakage, or other abnormality. | |

| Impact performance | Tube | Airtight test after dropping 2 kg of steel ball at a height of 1 m | No damage, cracks, exposure, etc |

| Yoke | Airtightness test after impact force | No damage, cracks, exposure, etc | |

| Endurance performance | Repeatability | 8 times according to the reference fastening condition | no abnormality |

| Airtightness | repeated adhesion test at 0.02 MPa for 1 minute | no leakage | |

| Heat resistance performance | Airtightness test after keeping 305mm hose at 427 degrees for 15 minutes | No damage, cracks, exposure, etc | |

| Stress corrosion performance | Exposure and deposition | Stainless steel : 180 degree bend Corrosion tested in a mixture of sodium chloride and sodium hypochlorite for 14 hours | No crack, etc |

| Airtightness | exposure (immersion) test at 0.02 Mpa for 1 minute | No leakage. | |

| Vibration performance | 610mm hose, 5kPa air pressure Amplitude 3.2 mm, 1000 times / minute, 55 minutes Repeat vibration and rest for 5 minutes Total 30 hour test | No leakage, etc. | |