Average equivalent length – 9.56

Flexible Sprinkler Drops (for export)

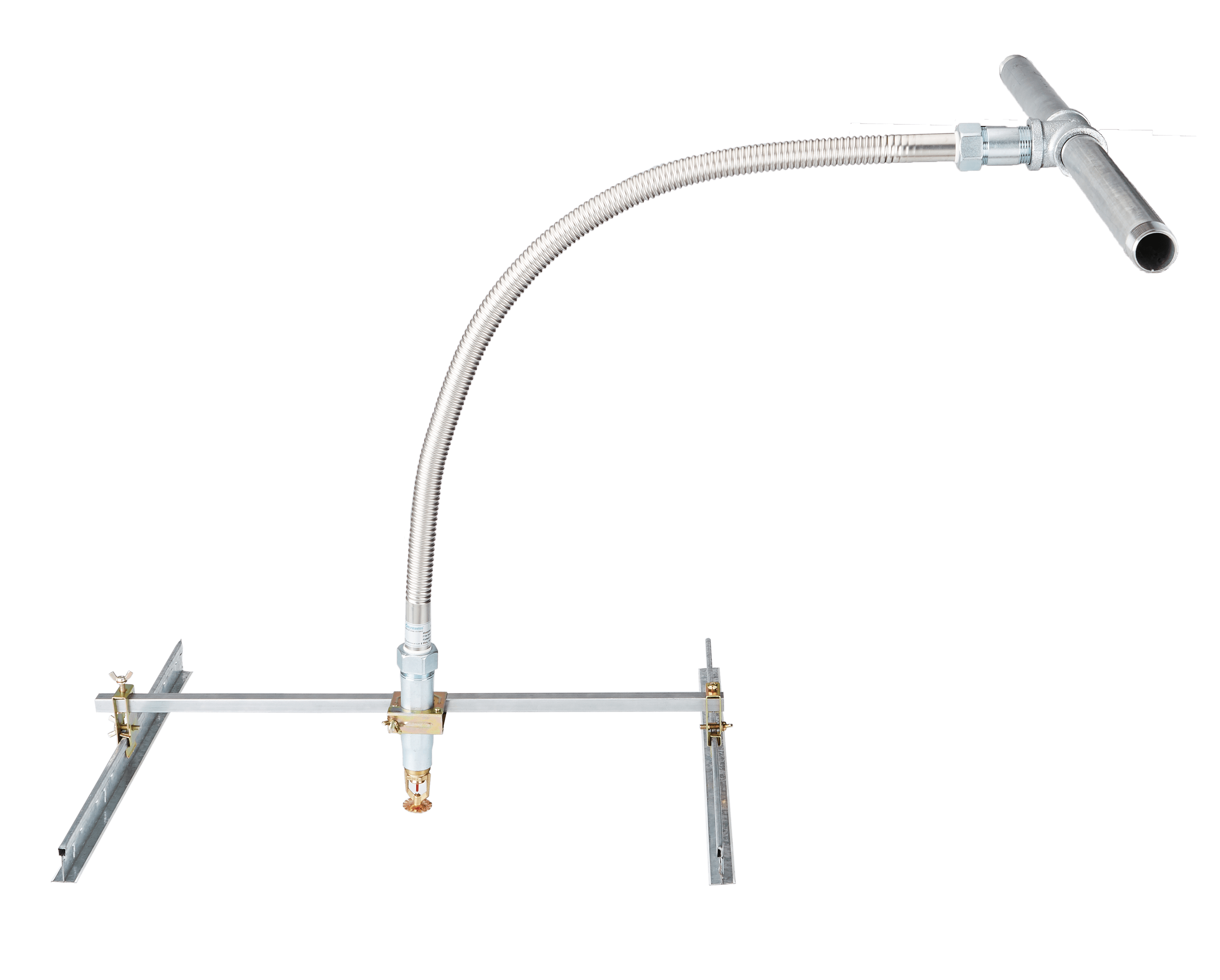

UNBRAIDED FLEXIBLE DROPS

- Stainless Steel 304

- Zinc-plated Steel (Nut & Nipple)

- EPDM Sealing Gasket

- Nylon Isolating Ring

- UL Listed

By essentially blocking pipe cutting and mid-pipe connections, you can save time and money efficiently.

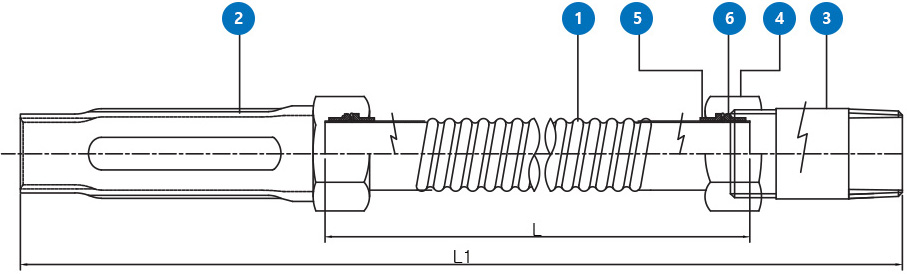

| 1. | Flexible tube | 3. | Nipple | 5. | Pressing ring |

|---|---|---|---|---|---|

| 2. | Reduce | 4. | Slip nut | 6. | Gasket |

| Manufacturable length | 700mm, 1000mm,1200mm, 1500mm, 1800mm |

|---|---|

| Outlet | 1/2” or 3/4” |

| Hose type | Unbraided |

| Hose | Stainless Steel 304 |

|---|---|

| Nuts & Nipples | Metal, Zinc plating |

| Sealing Gasket / Isolation Ring |

EPDM / NYLON |

| Max. Ambient temperature | 225℉ |

|---|---|

| Rated pressure | 200 psig (UL/ULC) |

|

New sprinkler hose related reducer / nipple assembly Permissible torque: 300 kgf.cm |

|

| Min. bend radius | 100mm (4") (UL/ULC) |

|

|---|---|---|

| Connector | ||

| Inlet | 1”NPT or BSPT | |

| Outlet | 1/2” or 3/4”NPT or BSPT | |

| Model | Rated Pressure, psig | Max. Ambient Temp, °F | Nom. Inlet by Outlet Size, in. | Assembly Length, mm | Max No. of 90° Bends | Min Bend Radius, mm. | Equivalent Length of 1 in. Schedule 40 Steel Pipe (C = 120), ft | Flexibility Type |

|---|---|---|---|---|---|---|---|---|

| DJ25UB-700 | 200 | 225 | 1x1/2 | 700 | 2 | 100 | 32 | Limited |

| DJ25UB-1000 | 200 | 225 | 1x1/2 | 1000 | 3 | 100 | 55 | Limited |

| DJ25UB-1200 | 200 | 225 | 1x1/2 | 1200 | 3 | 100 | 64 | Limited |

| DJ25UB-1500 | 200 | 225 | 1x1/2 | 1500 | 3 | 100 | 75 | Limited |

| DJ25UB-1800 | 200 | 225 | 1x1/2 | 1800 | 3 | 100 | 81 | Limited |

| DJ25UB-700 | 200 | 225 | 1x3/4 | 700 | 2 | 100 | 31 | Limited |

| DJ25UB-1000 | 200 | 225 | 1x3/4 | 1000 | 3 | 100 | 50 | Limited |

| DJ25UB-1200 | 200 | 225 | 1x3/4 | 1200 | 3 | 100 | 57 | Limited |

| DJ25UB-1500 | 200 | 225 | 1x3/4 | 1500 | 3 | 100 | 68 | Limited |

| DJ25UB-1800 | 200 | 225 | 1x3/4 | 1800 | 3 | 100 | 79 | Limited |

- Table 2

- Summary of pressure loss & equivalent length for1000 mm flexible hose with one 90° bend and terminated in a ½” outlet reducer

| Flow rate (l/min) |

Pressure upstream(bar) |

Pressure downstream(bar) |

Corrected pressure loss (bar) |

Eqivalent Length |

|---|---|---|---|---|

| 40 | 0.34 | 0.20 | 0.035 | 2.88 |

| 60 | 0.93 | 0.52 | 0.227 | 8.86 |

| 80 | 1.66 | 0.92 | 0.439 | 10.06 |

| 100 | 2.62 | 1.43 | 0.731 | 11.09 |

| 120 | 3.79 | 2.05 | 1.083 | 11.73 |

| 150 | 6.05 | 3.24 | 1.781 | 12.76 |

- Table 3

- Summary of pressure loss & equivalent length for1200 mm flexible hose with one 90° bend and terminated in a ½” outlet reducer

| Flow rate (l/min) |

Pressure upstream(bar) |

Pressure downstream(bar) |

Corrected pressure loss (bar) |

Eqivalent Length |

|---|---|---|---|---|

| 40 | 0.36 | 0.20 | 0.055 | 4.53 |

| 60 | 0.97 | 0.52 | 0.267 | 10.42 |

| 80 | 1.73 | 0.92 | 0.509 | 11.67 |

| 100 | 2.75 | 1.43 | 0.861 | 13.06 |

| 120 | 4.02 | 2.07 | 1.293 | 14.00 |

| 150 | 6.32 | 3.21 | 2.081 | 14.91 |

Average equivalent length – 11.43

- Table 4

- Summary of pressure loss & equivalent length for1500 mm flexible hose with one 90° bend and terminated in a ½” outlet reducer

| Flow rate (l/min) |

Pressure upstream(bar) |

Pressure downstream(bar) |

Corrected pressure loss (bar) |

Eqivalent Length |

|---|---|---|---|---|

| 40 | 0.37 | 0.20 | 0.065 | 5.36 |

| 60 | 0.98 | 0.52 | 0.277 | 10.81 |

| 80 | 1.76 | 0.93 | 0.529 | 12.13 |

| 100 | 2.77 | 1.43 | 0.881 | 13.37 |

| 120 | 4.03 | 2.08 | 1.313 | 14.22 |

| 150 | 6.35 | 3.22 | 2.101 | 15.06 |

Average equivalent length – 11.82

- Table 5

- Summary of pressure loss & equivalent length for1800 mm flexible hose with one 90° bend and terminated in a ½” outlet reducer

| Flow rate (l/min) |

Pressure upstream(bar) |

Pressure downstream(bar) |

Corrected pressure loss (bar) |

Eqivalent Length |

|---|---|---|---|---|

| 40 | 0.40 | 0.19 | 0.105 | 8.66 |

| 60 | 1.05 | 0.51 | 0.357 | 13.93 |

| 80 | 1.93 | 0.92 | 0.709 | 16.25 |

| 100 | 3.05 | 1.44 | 1.151 | 17.46 |

| 120 | 4.38 | 2.05 | 1.673 | 18.12 |

| 150 | 7.04 | 3.25 | 2.761 | 19.79 |

Average equivalent length – 15.70

| Part # | Description | Part # | Description |

|---|---|---|---|

| DJ25UB-700 | 1/2”x700mm Unbraided hose | DJ25UB-700 | 3/4”x700mm Unbraided hose |

| DJ25UB-1000 | 1/2”x1000mm Unbraided hose | DJ25UB-1000 | 3/4”x1000mm Unbraided hose |

| DJ25UB-1200 | 1/2”x1200mm Unbraided hose | DJ25UB-1200 | 3/4”x1200mm Unbraided hose |

| DJ25UB-1500 | 1/2”x1500mm Unbraided hose | DJ25UB-1500 | 3/4”x1500mm Unbraided hose |

| DJ25UB-1800 | 1/2”x1800mm Unbraided hose | DJ25UB-1800 | 3/4”x1800mm Unbraided hose |

* OD : 25.1mm / ID : 21.4mm STS 304

Underwriter’s Laboratories, Inc. (UL/ULC), cUL us 2443

International Building Code (IBC) Section 1621 / American Society of Civil Engineers (ASCE) 7.9.6.2.6.2 & 9.6.2.6.2.2

National Fire Protection Association (NFPA)

NFPA 13

Specification of new sprinkler piping and its accessories for firefighting service

NFPA 13D

Han / Two Family Residential Facilities and Manufacturing Plant Sprinkler System Installation Specification

NFPA 13R

4 or above residential building sprinkler system installation standard

NFPA 13 Section 9.2.1.3.3.3

Not more than 6 feet long without hangers Installation of flexible connection piping

American Society for Testing and Methods (ASTM)

ASTM C635

sound absorption tile rail panel ceiling metal suspension System-Related Manufacturing, Testing, and Specification

ASTM C636

Hinged Tile Rail Panel for Metal Suspension System Specification for installation of ceiling structure

Loss Prevention Certification Board (LPCB)

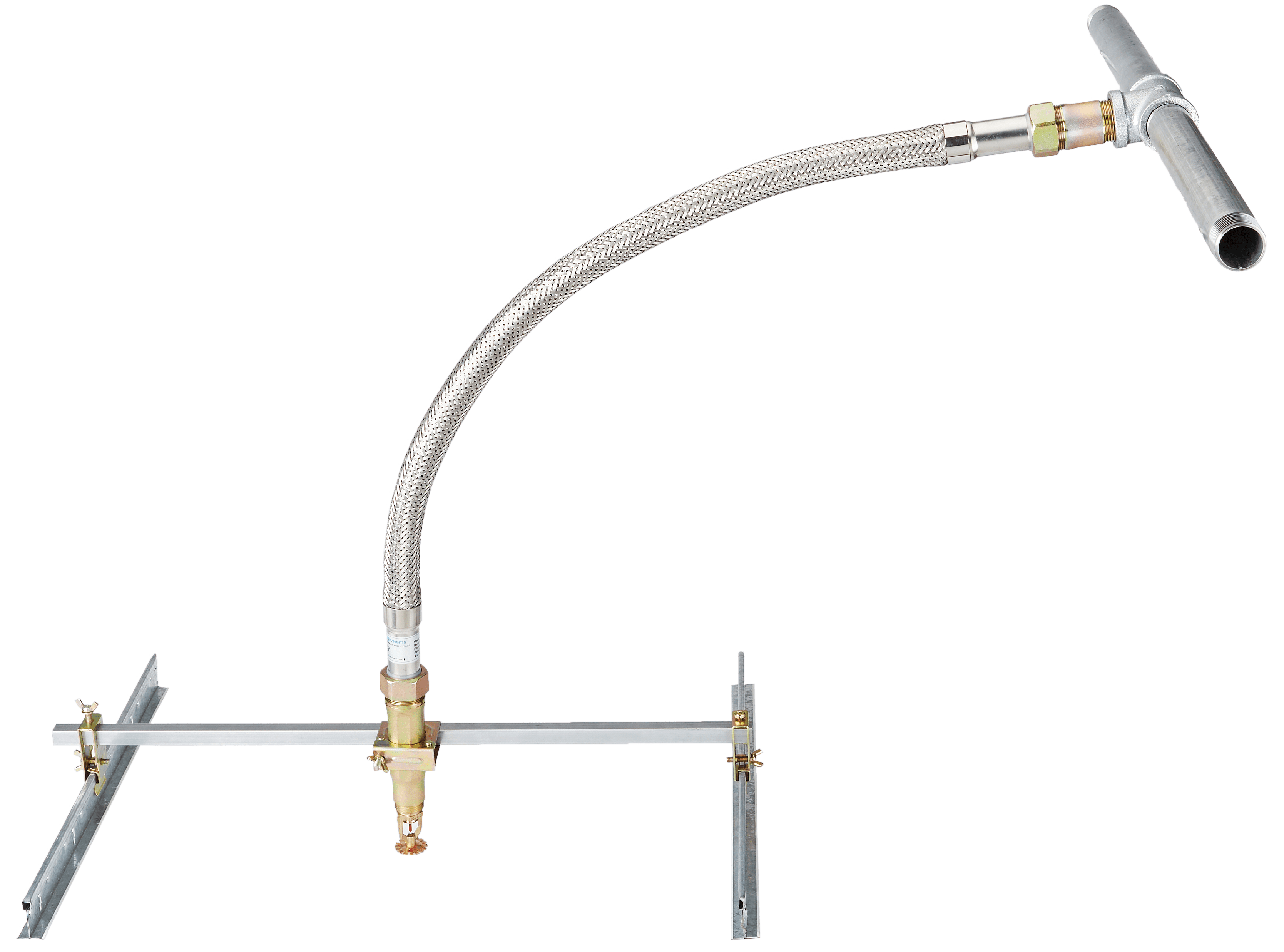

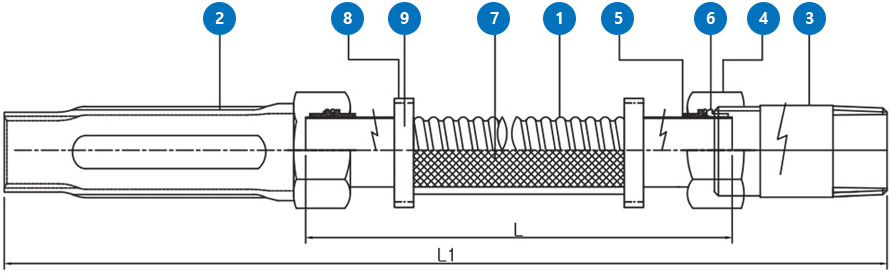

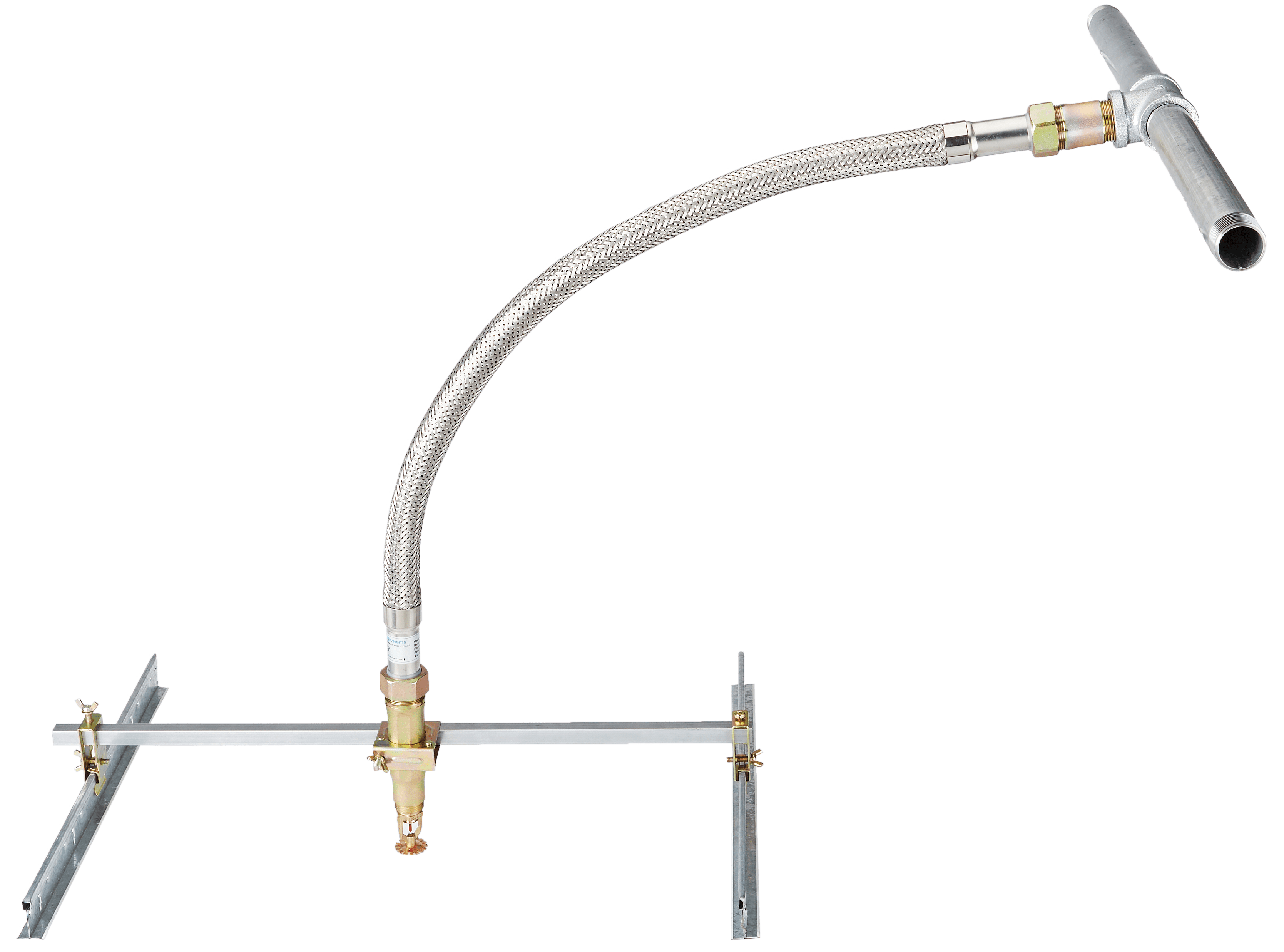

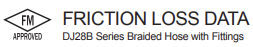

BRAIDED FLEXIBLE DROPS

- Stainless Steel 304

- Zinc-plated Steel (Nut & Nipple)

- EPDM Sealing Gasket

- Nylon Isolating Ring

- UL Listed & FM Approved

By essentially blocking pipe cutting and mid-pipe connections, you can save time and money efficiently.

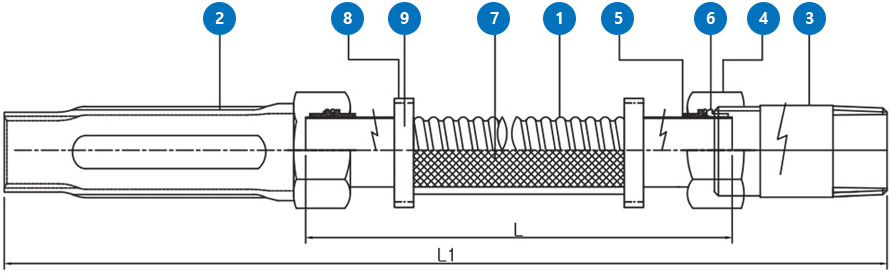

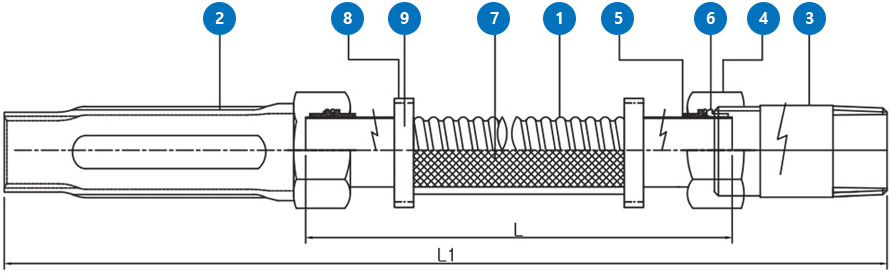

| 1. | Flexible tube | 4. | Slip nut | 7. | Braided Flexible Hose |

|---|---|---|---|---|---|

| 2. | Reduce | 5. | Pressing ring | 8. | Clamp(ouside) |

| 3. | Nipple | 6. | Gasket | 9. | Clamp(inside) |

| Manufacturable length | 24”, 36”, 48”, 60” and 72” |

|---|---|

| Outlet | 1/2” or 3/4” |

| Hose type | Braided |

| Hose | Stainless Steel 304 |

|---|---|

| Nuts & Nipples | Zinc-Plated Steel |

| Sealing Gasket / Isolation Ring |

EPDM / NYLON |

| Max. Ambient temperature | 225℉ |

|---|---|

| Rated pressure | 175 psig |

|

Required torque to assemble reducer and nipple with the flexible hose : 300kgf.cm |

|

| Min. bend radius | 190mm(UL/ULC) and 10”(FM) from connection nuts |

|

|---|---|---|

| Connector | ||

| Inlet | 1”NPT or BSPT | |

| Outlet | 1/2” or 3/4”NPT or BSPT | |

| Model | Rated Pressure, psig | Max. Ambient Temp, °F | Nom. Inlet by Outlet Size, in. | Assembly Length, ft (mm) | Max No. of 90° Bends | Min Bend Radius, mm. | Equivalent Length of 1 in. Schedule 40 Steel Pipe (C = 120), ft | Flexibility Type |

|---|---|---|---|---|---|---|---|---|

| DJ25B | 175 | 225 | 1x1/2 | 2.0 (610) | 1 | 7.5 (190.5) | 12 | Limited |

| 175 | 225 | 1x1/2 | 4.0 (1220) | 3 | 7.5 (190.5) | 29 | Limited | |

| 175 | 225 | 1x1/2 | 5.0 (1525) | 3 | 7.5 (190.5) | 68 | Limited | |

| 175 | 225 | 1x1/2 | 5.9 (1800) | 3 | 7.5 (190.5) | 94 | Limited |

| DJ25B | 175 | 225 | 1x3/4 | 2.0 (610) | 1 | 7.5 (190.5) | 21 | Limited |

| 175 | 225 | 1x3/4 | 4.0 (1220) | 3 | 7.5 (190.5) | 36 | Limited | |

| 175 | 225 | 1x3/4 | 5.0 (1525) | 3 | 7.5 (190.5) | 73 | Limited | |

| 175 | 225 | 1x3/4 | 5.9 (1800) | 3 | 7.5 (190.5) | 99 | Limited |

* UL : 19mm minimum bend radius, where C=120

| Model | NPT in |

k-Factor | Minimum Bend Radius in. (mm) |

Number of Bends |

Rated Working Pressure psi (kPa) |

Hose Assembly length in. (mm) |

Equivalent Length of 1 in. Schedule 40 Pipe, ft |

|---|---|---|---|---|---|---|---|

| DJ25B | 1/2 | 5.6 | 9 (230) | 1 | 175 (1205) | 2.3 ft | 22.9 (6.9) |

| 1/2 | 5.6 | 9 (230) | 2 | 175 (1205) | 3.3 ft | 34.6 (10.5) | |

| 1/2 | 5.6 | 9 (230) | 3 | 175 (1205) | 3.9 ft | 41.0 (12.5) | |

| 1/2 | 5.6 | 9 (230) | 4 | 175 (1205) | 4.9 ft | 50.4 (15.3) | |

| 1/2 | 5.6 | 9 (230) | 4 | 175 (1205) | 5.9 ft | 58.5 (17.8) |

| DJ25B | 3/4 | 8.0 | 9 (230) | 1 | 175 (1205) | 2.3 ft | 15.7 (4.8) |

| 3/4 | 8.0 | 9 (230) | 2 | 175 (1205) | 3.3 ft | 26.9 (8.2) | |

| 3/4 | 8.0 | 9 (230) | 3 | 175 (1205) | 3.9 ft | 34.8 (10.6) | |

| 3/4 | 8.0 | 9 (230) | 4 | 175 (1205) | 4.9 ft | 43.8 (13.5) | |

| 3/4 | 8.0 | 9 (230) | 4 | 175 (1205) | 5.9 ft | 53.4 (16.2) |

* FM : 10” minimum bend radius, where C=120

| Part # | Description | Part # | Description |

|---|---|---|---|

| DJ25B-24 | 1/2”x24” Braided hose | DJ25B-24 | 3/4”x24” Braided hose |

| DJ25B-36 | 1/2”x36” Braided hose | DJ25B-36 | 3/4”x36” Braided hose |

| DJ25B-48 | 1/2”x48” Braided hose | DJ25B-48 | 3/4”x48” Braided hose |

| DJ25B-60 | 1/2”x60” Braided hose | DJ25B-60 | 3/4”x60” Braided hose |

| DJ25B-72 | 1/2”x72” Braided hose | DJ25B-72 | 3/4”x72” Braided hose |

* FM : 10” minimum bend radius, where C=120

Underwriter’s Laboratories, Inc. (UL/ULC), cUL us 2443

International Building Code (IBC) Section 1621 / American Society of Civil Engineers (ASCE) 7.9.6.2.6.2 & 9.6.2.6.2.2

National Fire Protection Association (NFPA)

NFPA 13

Specification of new sprinkler piping and its accessories for firefighting service

NFPA 13D

Han / Two Family Residential Facilities and Manufacturing Plant Sprinkler System Installation Specification

NFPA 13R

4 or above residential building sprinkler system installation standard

NFPA 13 Section 9.2.1.3.3.3

Not more than 6 feet long without hangers Installation of flexible connection piping

American Society for Testing and Methods (ASTM)

ASTM C635

sound absorption tile rail panel ceiling metal suspension System-Related Manufacturing, Testing, and Specification

ASTM C636

Hinged Tile Rail Panel for Metal Suspension System Specification for installation of ceiling structure

BRAIDED FLEXIBLE DROPS

- Stainless Steel 304

- Zinc-plated Steel (Nut & Nipple)

- EPDM Sealing Gasket

- Nylon Isolating Ring

- UL Listed & FM Approved

By essentially blocking pipe cutting and mid-pipe connections, you can save time and money efficiently.

| 1. | Flexible tube | 4. | Slip nut | 7. | Braided Flexible Hose |

|---|---|---|---|---|---|

| 2. | Reduce | 5. | Pressing ring | 8. | Clamp(ouside) |

| 3. | Nipple | 6. | Gasket | 9. | Clamp(inside) |

| Manufacturable length | 24”, 36”, 48”, 60” and 72” |

|---|---|

| Outlet | 1/2” or 3/4” |

| Hose type | Braided |

| Hose | Stainless Steel 304 |

|---|---|

| Nuts & Nipples | Zinc-Plated Steel |

| Sealing Gasket / Isolation Ring |

EPDM / NYLON |

| Max. Ambient temperature | 225℉ |

|---|---|

| Rated pressure | 200 psig |

|

Required torque to assemble reducer and nipple with the flexible hose : 300kgf.cm |

|

| Min. bend radius | 3"(UL/ULC) and 9”(FM) | |

|---|---|---|

| Connector | ||

| Inlet | 1”NPT or BSPT | |

| Outlet | 1/2” or 3/4”NPT or BSPT | |

| Model | Rated Pressure, psig | Max. Ambient Temp, °F | Nom. Inlet by Outlet Size, in. | Assembly Length, ft (mm) | Max No. of 90° Bends | Min Bend Radius, mm. | Equivalent Length of 1 in. Schedule 40 Steel Pipe (C = 120), ft | Flexibility Type |

|---|---|---|---|---|---|---|---|---|

| DJ28B-700 | 200 | 225 | 1x1/2 | 2.3(700) | 3 | 3 | 18 | Limited |

| DJ28B-1000 | 200 | 225 | 1x1/2 | 3.3(1000) | 5 | 3 | 23 | Limited |

| DJ28B-1200 | 200 | 225 | 1x1/2 | 3.9(1200) | 7 | 3 | 29 | Limited |

| DJ28B-1500 | 200 | 225 | 1x1/2 | 4.9(1500) | 9 | 3 | 39 | Limited |

| DJ28B-1800 | 200 | 225 | 1x1/2 | 5.9(1800) | 12 | 3 | 50 | Limited |

| DJ28B-700 | 200 | 225 | 1x3/4 | 2.3(700) | 3 | 3 | 20 | Limited |

| DJ28B-1000 | 200 | 225 | 1x3/4 | 3.3(1000) | 5 | 3 | 24 | Limited |

| DJ28B-1200 | 200 | 225 | 1x3/4 | 3.9(1200) | 7 | 3 | 31 | Limited |

| DJ28B-1500 | 200 | 225 | 1x3/4 | 4.9(1500) | 9 | 3 | 40 | Limited |

| DJ28B-1800 | 200 | 225 | 1x3/4 | 5.9(1800) | 12 | 3 | 70 | Limited |

* UL : 19mm minimum bend radius, where C=120

| Model | NPT in |

k-Factor | Minimum Bend Radius in. (mm) |

Number of Bends |

Rated Working Pressure psi (kPa) |

Hose Assembly length in. (mm) |

Equivalent Length of 1 in. Schedule 40 Pipe, ft |

|---|---|---|---|---|---|---|---|

| DJ28B | 1/2 | 5.6 | 9 (230) | 1 | 200 (1380) | 2.3 (0.7) | 22.9 (6.9) |

| 1/2 | 5.6 | 9 (230) | 2 | 200 (1380) | 3.3 (1.0) | 34.6 (10.5) | |

| 1/2 | 5.6 | 9 (230) | 3 | 200 (1380) | 3.9 (1.2) | 41.0 (12.5) | |

| 1/2 | 5.6 | 9 (230) | 4 | 200 (1380) | 4.9 (1.5) | 50.4 (15.3) | |

| 1/2 | 5.6 | 9 (230) | 4 | 200 (1380) | 5.9 (1.8) | 58.5 (17.8) |

| DJ28B | 3/4 | 8.0 | 9 (230) | 1 | 200 (1380) | 2.3 (0.7) | 15.7 (4.8) |

| 3/4 | 8.0 | 9 (230) | 2 | 200 (1380) | 3.3 (1.0) | 26.9 (8.2) | |

| 3/4 | 8.0 | 9 (230) | 3 | 200 (1380) | 3.9 (1.2) | 34.8 (10.6) | |

| 3/4 | 8.0 | 9 (230) | 4 | 200 (1380) | 4.9 (1.5) | 43.8 (13.5) | |

| 3/4 | 8.0 | 9 (230) | 4 | 200 (1380) | 5.9 (1.8) | 53.4 (16.2) |

* FM : 9” minimum bend radius, where C=120

| Part # | Description | Part # | Description |

|---|---|---|---|

| DJ28B-700 | 1/2”x700 Braided hose | DJ28B-700 | 3/4”x700 Braided hose |

| DJ28B-1000 | 1/2”x1000 Braided hose | DJ28B-1000 | 3/4”x1000 Braided hose |

| DJ28B-1200 | 1/2”x1200 Braided hose | DJ28B-1200 | 3/4”x1200 Braided hose |

| DJ28B-1500 | 1/2”x1500 Braided hose | DJ28B-1500 | 3/4”x1500 Braided hose |

| DJ28B-1800 | 1/2”x1800 Braided hose | DJ28B-1800 | 3/4”x1800 Braided hose |

* OD : 28.0mm / ID : 27.4mm STS 304 1/2”x1800 Braided

Underwriter’s Laboratories, Inc. (UL/ULC), cUL us 2443

International Building Code (IBC) Section 1621 / American Society of Civil Engineers (ASCE) 7.9.6.2.6.2 & 9.6.2.6.2.2

National Fire Protection Association (NFPA)

NFPA 13

Specification of new sprinkler piping and its accessories for firefighting service

NFPA 13D

Han / Two Family Residential Facilities and Manufacturing Plant Sprinkler System Installation Specification

NFPA 13R

4 or above residential building sprinkler system installation standard

NFPA 13 Section 9.2.1.3.3.3

Not more than 6 feet long without hangers Installation of flexible connection piping

American Society for Testing and Methods (ASTM)

ASTM C635

sound absorption tile rail panel ceiling metal suspension System-Related Manufacturing, Testing, and Specification

ASTM C636

Hinged Tile Rail Panel for Metal Suspension System Specification for installation of ceiling structure

BRAIDED FLEXIBLE DROPS

- Stainless Steel 304

- Zinc-plated Steel (Nut & Nipple)

- EPDM Sealing Gasket

- Nylon Isolating Ring

- FM Approved

By essentially blocking pipe cutting and mid-pipe connections, you can save time and money efficiently.

| 1. | Tubular flexible tube | 4. | Slip nut | 7. | Braided Flexible Hose |

|---|---|---|---|---|---|

| 2. | Reduce | 5. | Pressing ring | 8. | Clamp(ouside) |

| 3. | Nipple | 6. | Gasket | 9. | Clamp(inside) |

| Manufacturable length | 24”, 36”, 48”, 60” and 72” |

|---|---|

| outlet | 1/2” or 3/4” |

| Hose type | Braided |

| hose | Stainless Steel 304 |

|---|---|

| Nuts & Nipples | Zinc-Plated Steel |

| Sealing Gasket / Isolation Ring |

EPDM / NYLON |

| Maximum attention temperature | 225℉ |

|---|---|

| Maximum working pressure | 175 psig |

|

Required torque to assemble reducer and nipple with the flexible hose : 300kgf.cm |

|

| Minimum bending radius | 8”(FM) from connection nuts |

|

|---|---|---|

| Connector | ||

| Inlet | 1”NPT or BSP | |

| Outlet | 1/2” or 3/4”NPT or BSP | |

| Model | NPT in |

k-Factor | Minimum Bend Radius in. (mm) |

Number of Bends |

Rated Working Pressure psi (kPa) |

Hose Assembly length in. (mm) |

Equivalent Length of 1 in. Schedule 40 Pipe, ft |

|---|---|---|---|---|---|---|---|

| DJ32B | 1/2 | 5.6 | 9 (230) | 1 | 175 (1205) | 2.3 ft | 22.9 (6.9) |

| 1/2 | 5.6 | 9 (230) | 2 | 175 (1205) | 3.3 ft | 34.6 (10.5) | |

| 1/2 | 5.6 | 9 (230) | 3 | 175 (1205) | 3.9 ft | 41.0 (12.5) | |

| 1/2 | 5.6 | 9 (230) | 4 | 175 (1205) | 4.9 ft | 50.4 (15.3) | |

| 1/2 | 5.6 | 9 (230) | 4 | 175 (1205) | 5.9 ft | 58.5 (17.8) |

| DJ32B | 3/4 | 8.0 | 9 (230) | 1 | 175 (1205) | 2.3 ft | 15.7 (4.8) |

| 3/4 | 8.0 | 9 (230) | 2 | 175 (1205) | 3.3 ft | 26.9 (8.2) | |

| 3/4 | 8.0 | 9 (230) | 3 | 175 (1205) | 3.9 ft | 34.8 (10.6) | |

| 3/4 | 8.0 | 9 (230) | 4 | 175 (1205) | 4.9 ft | 43.8 (13.5) | |

| 3/4 | 8.0 | 9 (230) | 4 | 175 (1205) | 5.9 ft | 53.4 (16.2) |

* FM : 8” minimum bend radius, where C=120

| Part # | Description | Part # | Description |

|---|---|---|---|

| DJ32B-C24 | 1/2”x24” Braided hose | DJ32B-C24 | 3/4”x700 Braided hose |

| DJ32B-C36 | 1/2”x36” Braided hose | DJ32B-C36 | 3/4”x1000 Braided hose |

| DJ32B-C48 | 1/2”x48” Braided hose | DJ32B-C48 | 3/4”x1200 Braided hose |

| DJ32B-C60 | 1/2”x60” Braided hose | DJ32B-C60 | 3/4”x1500 Braided hose |

| DJ32B-C724 | 1/2”x72” Braided hose | DJ32B-C72 | 3/4”x1800 Braided hose |

* OD : 32.0mm / ID : 26.1mm STS 304 1/2”x72” Braided hose

Underwriter’s Laboratories, Inc. (UL/ULC), cUL us 2443

International Building Code (IBC) Section 1621 / American Society of Civil Engineers (ASCE) 7.9.6.2.6.2 & 9.6.2.6.2.2

National Fire Protection Association (NFPA)

NFPA 13

Specification of new sprinkler piping and its accessories for firefighting service

NFPA 13D

Han / Two Family Residential Facilities and Manufacturing Plant Sprinkler System Installation Specification

NFPA 13R

4 or above residential building sprinkler system installation standard

NFPA 13 Section 9.2.1.3.3.3

Not more than 6 feet long without hangers Installation of flexible connection piping

American Society for Testing and Methods (ASTM)

ASTM C635

sound absorption tile rail panel ceiling metal suspension System-Related Manufacturing, Testing, and Specification

ASTM C636

Hinged Tile Rail Panel for Metal Suspension System Specification for installation of ceiling structure